Product introduction

CTC has the advantages of high space utilization, great reducing of the load loss and the winding hot spot temperature rise, also improvement of the winding's mechanical strength. The windings will be simple and less time to be winded, but deserve the compact structure. CTC is mainly used to manufacture windings of power transformers, reactors and traction transformers.

Product features

? Conductor dimension precision A: ±0.005mm B: ±0.01mm

? Yield strength (Cu) 80-300N/mm² Yield strength (Al) 60-90N/mm²

? Accurate in shape and size

? Short transposition pitch with smooth S bend

? Proper tightness of wrapping

? More than 3500 meters without joint

? High temperature self-adhesive/Broadsided self-adhesive

Product categories

? Paper insulated PVF CTC

? Polyester netting PVF CTC

? Aromatic polyamide paper (Nomex) insulated PVF CTC

? Fiber glass wrapping combined CTC

? High temperature self-bonded PVF CTC

? Broadsided self-adhesive CTC

Technical parameters

Category

Item |

Cu |

Al |

|

Number of transposable strands |

5~83 (odd or even optional) |

|

Single conductor thickness |

0.80-3.15mm |

1.20-3.15mm |

|

Single conductor width |

3.00-13.00mm |

|

Transposing pitch |

≥38mm |

Insulation Material

Power cable paper, high density insulation paper, Thermal upgraded paper, high elongation fiber paper, aromatic polyamide paper (Nomex) , PET film

Users can specify the brand, model and specification of insulation materials

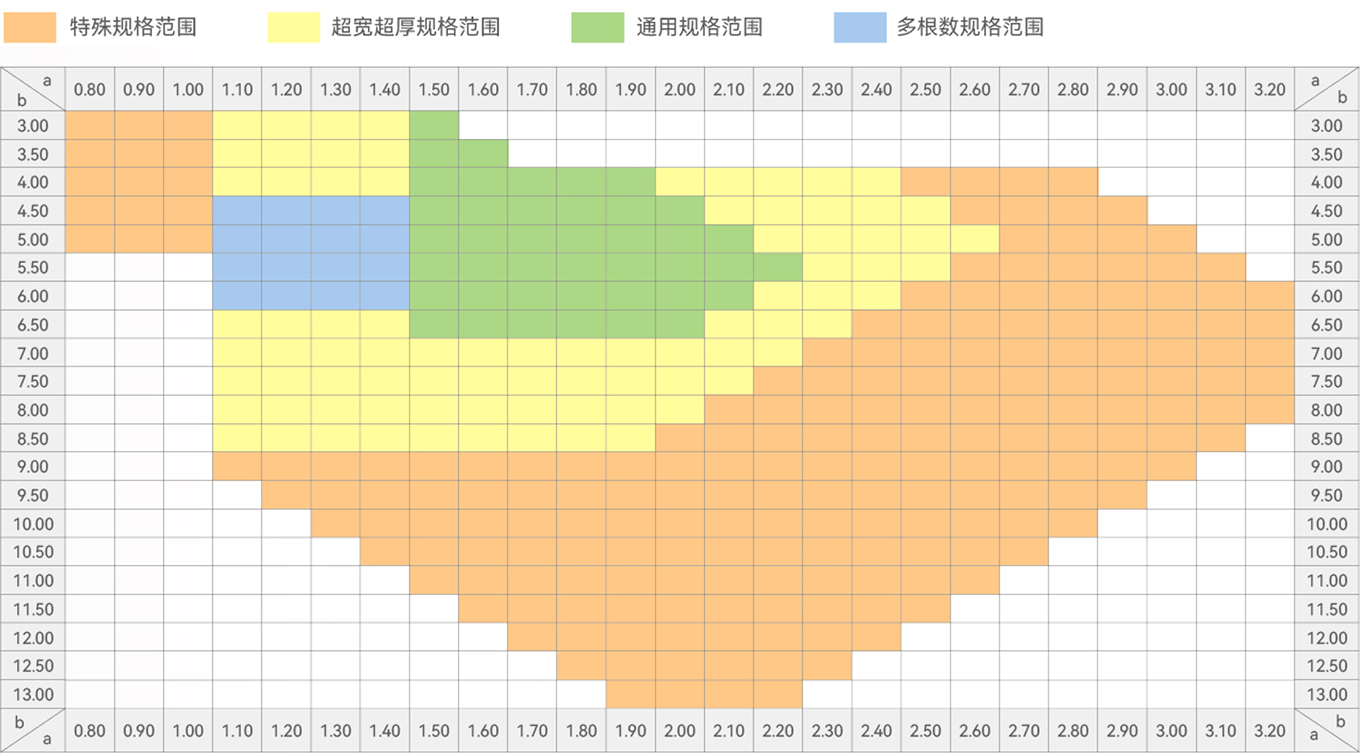

CTC (Cu) data sheet

Remark 1: the sectional areas of CTC are effected by the single conductor's wide-thickness ratio, therefore there are different specifications of CTC which we will do the classifications here.

Remark 2: CTC(Al)refer to the technical parameters and the table above